Moddler offers a variety of printing technologies and material options. We can help guide you in choosing the materials best suited for your project. Here is some quick information on each to help you determine the right material and process for your project.

Turnaround time:

Our standard turnaround is 2-3 business days. For those needing faster turnaround we offer Same Day and Next Day expedite options. Check the chart below below to see what turn around we offer for the given material:

Polyjet

Polyjet

FDM

Polyjet

FDM

SLA

Polyjet printing technology offers some of the all-around best parts available with high resolution, large build envelope, and fast print times. Polyjet parts sand easily, take paint well, and are great for gluing. The capability of high accuracy allows for test fitting and snapping parts.

These parts are great for final validation before manufacturing, masters for molds, finishing and painting, Checking snap fit and form. Can be used for many applications such as architectural models, product prototypes and enclosures, figurines, and proof of concept models. Printing resolution can be as good as 15 micron layers (thinner than a strand of hair) and offer tolerances of .02mm. Build bed sizes can go as large as 20” x 15” x 8”. Larger parts can seamlessly be aligned and assembled with keying systems.

Material Options:

* Materials require a material swap fee of $200

* * Rubber-Like has Shore-A hardness scaled options of 27, 40, 50, 60, 70, 85, and 95.

Benefits of Polyjet parts:

Benefits of Polyjet parts:

FDM or Fused Deposit Modeling printing is great for cheap, early prototypes and more durable parts. FDM technology offers mid to low resolution parts. ABS and PLA materials are the most commonly used filament for FDM printers but we offer a variety of material options. ABS material can be sanded with some effort and can be used to print large parts. PLA parts are often the cheapest offered and can be used for initial form and size testing.

Material Options:

* Other colors available with extended turn around time and at additional cost

Benefits of FDM parts:

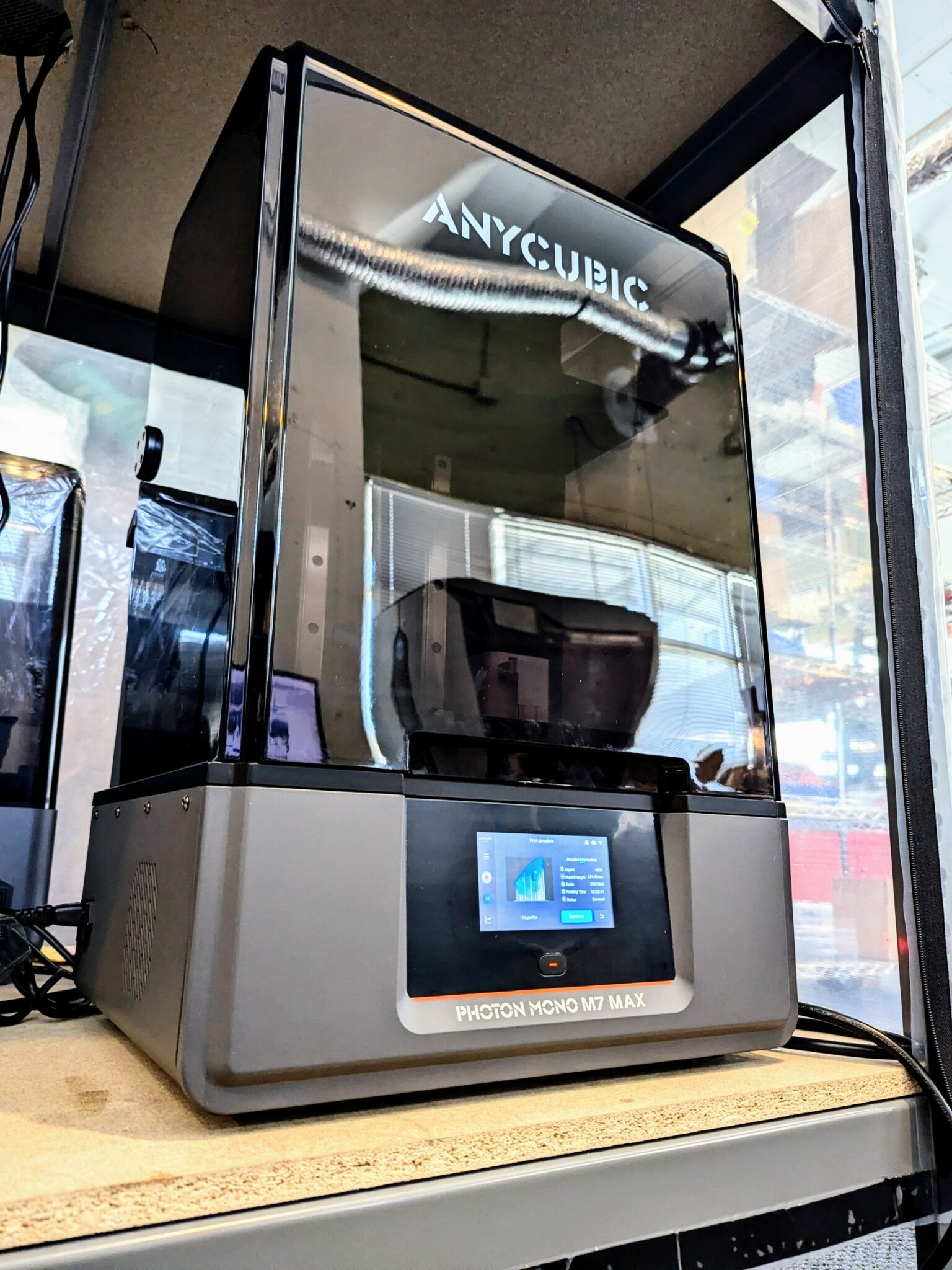

SLA printers offer the highest surface finish parts available. They are great for printing high detail, small pieces such as miniatures and jewelry, as well as larger, complex models. These parts can also be used as masters for mold making due to high surface finish and low visibility build lines.

Material options:

Benefits of SLA/DLP parts:

Benefits of SLA parts:

For those needing asthetic or cosmetic models, check out our post-processing service options that take 3d prints to the next level!

Copyright © 2025 Artifactory3d

Copyright © 2025 Moddler